SK Hynix starts mass producing the “world’s first” 128-layer 4D NAND chips

SK Hynix starts mass producing the “world’s first” 128-layer 4D NAND chips

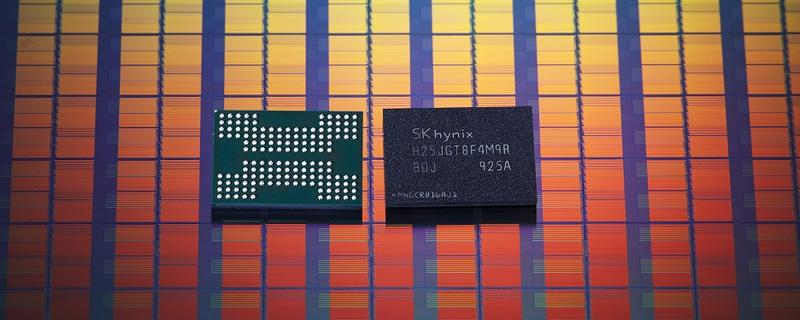

SK Hynix has announced that they have started to mass produce the world’s first 1Tb 128-layer TLC NAND chips using their 4DÂ CTF-based (Charge Trap Flash) NAND flash technology. Why 4D? SK Hynix 4D technology moves a structure known as the periphery under their 3D NAND technology, creating a PUC (Periphery Under Cell) flash chip. The 4th dimension is the structures that have been moved under SK Hynix’ 3D NAND structure. Yes, this isn’t a real 4D structure…Â

With the company’s new 128-layer 1Tb chips, SK Hynix can provide increased productivity per wafer, offering 40% gains over the company’s existing 96-layer 4D NAND. In addition to this, SK Hynix has claimed that this technology migration costed 60% less than their previous technological shift, delivering surprising levels of investment efficiency. Â

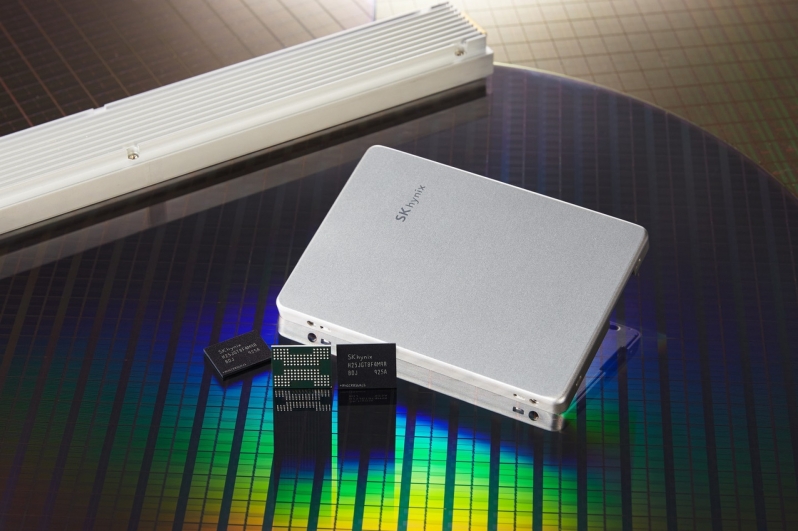

SK Hynix plans to ship its 4D NAND in the second half of this year, promising data transfer rates of 1,400 Mbps at 1.2V, enabling high-performance levels for mobile devices. SK Hynix also plans to create a 2TB client SSD in-house using this NAND and an SK Hynix-designed controller chip. 16TB and 32TB NVMe SSDs are also planned for the enterprise market.Â

Moving forward, SK Hynix plans to develop next-generation NAND with 176 layers of NAND cells, with aims to further increase the company’s productivity per wafer and deliver higher storage capacities per chip. Â

You can join the discussion on SK Hynix starting mass production of the “world’s first” 128-layer 1Tb 3D/4D NAND chips on the OC3D Forums.Â