xTool P2 CO2 Laser Cutter Review

Unboxing and Setup

Unboxing

The xTool P2 measures in at 1000 x 639 x 268mm and weighs 45Kg. This is a large and heavy machine, and its box is colossal. You will need at least two people to unbox and set up this machine. It’s simply too large and heavy for a single person to move.

xTool have done a great job packaging this unit. The unit is surrounded by foam, ensuring that it remains intact during transit. This is the kind of protection that I expect to see from such a large and premium product.

Setup – Filling the xTool P2 with Coolant

While the machine itself is pre-assembled, P2 users will need to complete a few steps before they start laser cutting. Unlike the GlowForge, the xTool P2 isn’t pre-filled with coolant. Users will need to fill their machines themselves. This is why the P2 ships with a bottle of anti-freeze.

First users will need to remove a panel from the P2 to gain access to its coolant chamber.

To fill the P2 with coolant, you will need purified or de-ionised water. This should be available at your local hardware store or garage at a very low cost. This is what you will be using as coolant for this laser cutter. If you are storing you P2 in a place that may reach negative temperatures, you will need to use a mix of purified water and anti-freeze as coolant.

In the xTool P2’s instructions, there is a handy chart that you can use to see what concentration of anti-freeze your machine will need.

Our advice is to pour the P2’s anti-freeze into a secondary container and then use its original bottle to mix your purified water and anti-freeze. This bottle has measurements on the side to help you achieve the correct mixture. Use the funnel provided to prevent unnecessary spillages.

Once you have the correct mix, you can now fill the P2’s coolant chamber as instructed. Please follow the P2’s instructions carefully to prevent any issues. Once finished, you can re-attatch any panels you removed and your machine is one step closer to being usable.

Setup – Where do exhaust gases go?

Laser cutters work by using a laser to burn materials. Burning materials produce smoke and other particulate matter, and those gasses need to go somewhere. Below is the xTool P2’s exhaust port, which uses a fan to exhaust gases out the rear of the machine.

Users of the P2 can use the machine’s included air duct to push exhaust gases outside of your workspace (out a window perhaps). Alternatively, users can utilise xTool’s air purifier add-on to clean this exhaust air. Since we were not provided with the P2’s air purifier add-on, we simply placed our exhaust hose out a nearby window.

Setup – calibrating the laser

The xTool P2 is a class 4 laser cutter, making it a dangerous product for anyone using it incorrectly. Part of the P2’s initial setup is to calibrate its laser. This includes adjusting the unit’s mirrors to ensure that the P2’s laser is correctly oriented. Users must carefully follow the steps in the P2’s instructions to ensure that the laser works as intended.

This calibration will be a turn-off for many potential P2 users. After all, most people do not want to mess with industrial-grade lasers. Products like the Glowforge simply work out of the box, making them easier to use. That said, this calibration step allows xTool P2 users to learn how their machine works, which is useful knowledge for when maintenance is eventually required.

P2 users will need to use xTool’s Creative Space software to test their laser. Again, users should follow xTool’s instructions carefully to prevent any issues.

Once calibrated, your laser will be directed into the laser aperture ready for use. The tape seen below is used to showcase that the laser is now adjusted correctly.

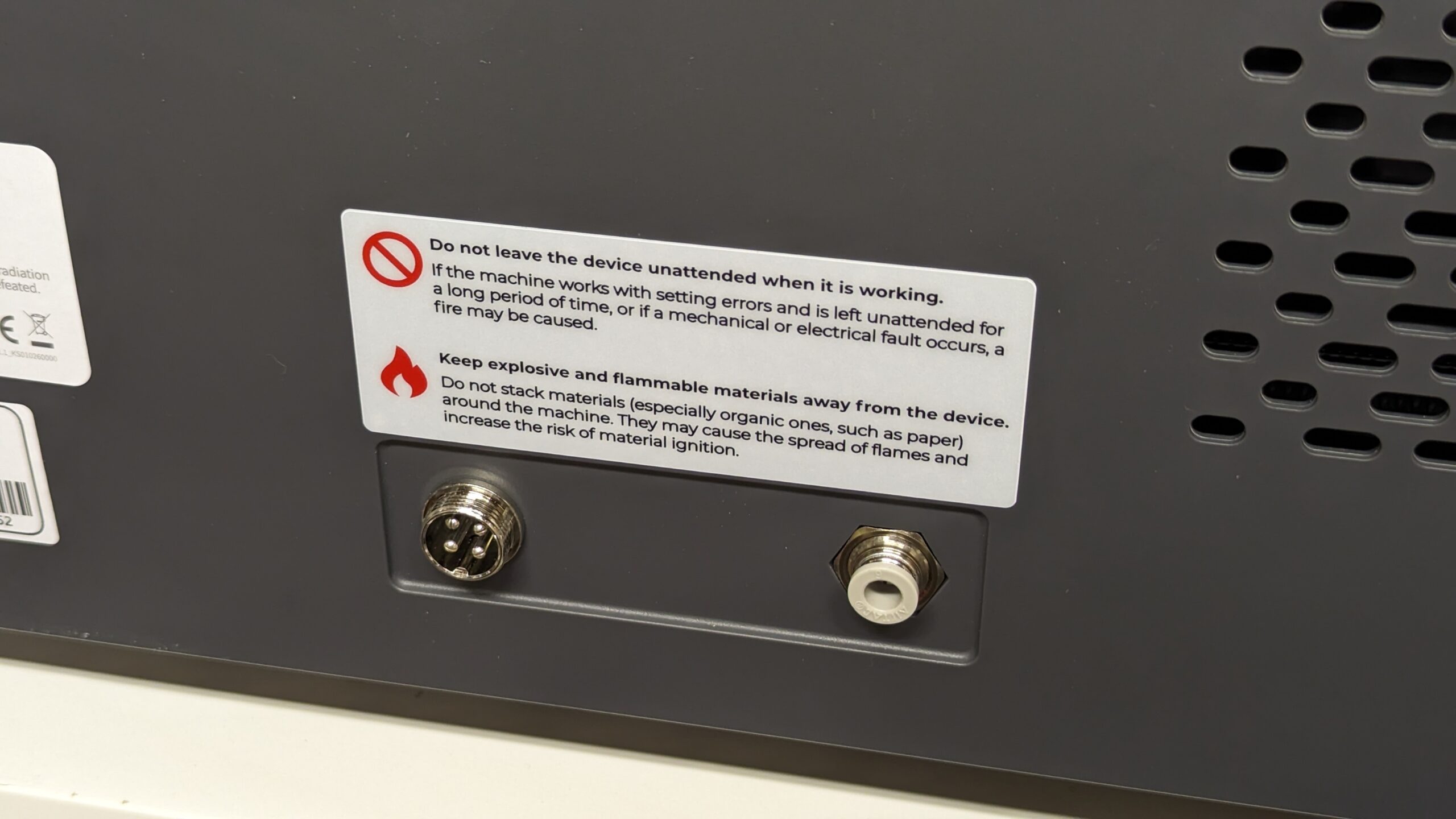

Fire Safety

The xTool P2 is not designed to be left unattended when in use. Users should keep an eye on the machine when it is operating, especially when using unfamiliar materials. Unlike other hobbies and lower-end professional lasers, the P2 can be connected to a fire safety systems. xTool even have their own fire safety system add-on for their P2 laser, which can detect fires and extinguish fires without damaging the laser. This add-on will make the P2 safer to use than many competing products.